Home / Materials / Glasses And Quartz / Fused Quartz / Fused Silica

The presence of OH impurity is difficult to limit, but it is key to allow highest levels of IR transmission. The Infrared grades have some metallic impurities from manufacture, which limit their UV transmission. Fused silica grades termed UV grade are better controlled from these metals, and so they transmit further into UV ranges. But their drawback is OH caused absorption, especially at 2.2um and 2.7um.

These terms are sometimes used interchangeably, although there are differences. Both are essentially pure silicon dioxide, but methods of manufacture and resulting impurities do create subtle physical and significant optical variations. Fused quartz is typically produced by melting crystalline sand and then purifying. Several purity grades of this amorphous material are commercially available. Fused silica is produced after a reaction from SiCl4 gas. Chemical purity is controllable to higher levels than typical when starting with natural materials.

All SiO2 glasses share some properties, including extreme hardness, very low thermal conductivity, low thermal expansion, and a wide range of optical transmission from UV to IR. This material provides very high thermal shock resistance as well. Since the fused quartz/silica is amorphous, some general features are possible to be formed at high temperature, including achievement of a clear (flame polished) surface. It is important to note, however, that thermal forming and subsequent cooling will create high stresses in the material. To some extent, the stresses can be relieved by controlled anneal processes. Manufacturers offer a wide assortment of standard size tubes up to approximately one meter in length. Large plates are also offered in standard sizes or custom taken from large single melt boules.

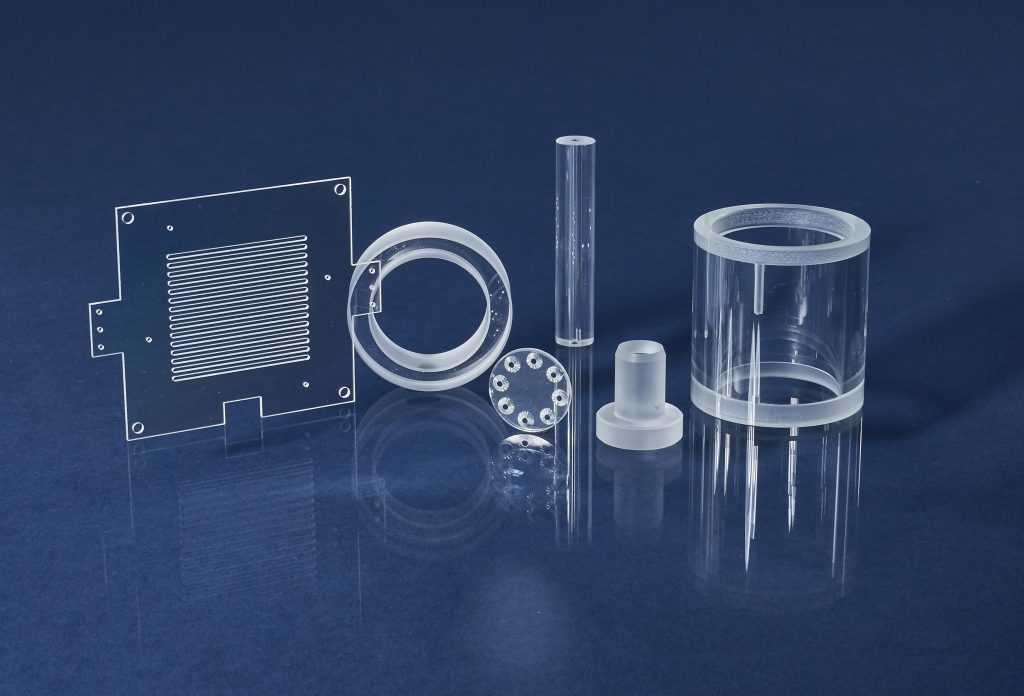

For complex features and tight dimensional control, precision components are usually machined by use of diamond grinding technology. SiO2 is very hard (Mohs 7) and will not survive single-point cutting operations. Diamond grinding is successful and can achieve most desired features, including high levels of polish.

SiO2 can also be grown as a single crystal. The crystal offers some piezoelectric features. Availability is limited.

INSACO has experience in sourcing fused quartz from multiple high-quality producers in sizes sufficient to fabricate as customer specified precision parts. Where mechanical properties are most important, we suggest fused quartz, as those materials are more readily available. If optical properties – especially at extremes of UV and IR – are key to finished part performance, we suggest our customers select from fused silica offerings.

Applications for machined fused quartz and fused silica include specialty laboratory equipment and instrumentation, and semiconductor fabrication equipment. High-precision microwave circuitry and some mirror and lens applications will also benefit.